Three Pillars: Cast Steel, Forging and 3D Printing / Shaping the Future with Our Proprietary Technologies

At our technology-driven company, we specialize in the research and development of functional alloys and special steels that do not yet exist in the market.

We are committed to delivering the optimal alloys to meet the ever-evolving needs of diverse industries.

Centered around our steel casting business, we offer a wide range of manufacturing methods, including forged materials, rolled materials, and wire rods, to create products tailored to our customers' specific requirements.

Looking ahead to future demands, we are also pioneering advancements in metal 3D printing, enabling the production of complex geometries and lightweight designs that were once considered impossible.

Casting Business

At the heart of our operations lies our flagship product, low thermal expansion cast steel (Invar alloy), alongside a diverse range of high-performance alloys, including heat-resistant, wear-resistant, and corrosion-resistant materials.

Our state-of-the-art foundry produces cast steel components ranging from 10 kg to an impressive 5 tons in weight. For even larger-scale projects, we collaborate seamlessly with trusted partners both domestically and internationally.

While casting is an age-old craft, the precision required to transform molten metal into solid, high-quality components demands cutting-edge expertise and advanced technology. With over 70 years of experience and the integration of the latest casting simulation technologies, we are proud to lead the way in delivering innovative, high-quality cast steel solutions to meet the evolving needs of industries worldwide.

Experience the fusion of tradition and innovation with our world-class cast steel products.

Shaped Material Business

In our shaped material business, we transform steel ingots produced in our casting operations into a variety of high-performance products, including forged components, rolled materials, and drawn wires.

Additionally, we offer value-added services such as high-precision machining and surface treatments like plating, ensuring that our products meet the most demanding specifications.

By combining advanced processing techniques with meticulous attention to detail, we deliver tailored solutions that exceed customer expectations and drive success across industries.

Leveraging a robust network of trusted partner companies, our skilled engineers in the Shaped Material Division design and deliver optimal manufacturing solutions tailored to product specifications and cost efficiency.

AM Business (3D Printing Business)

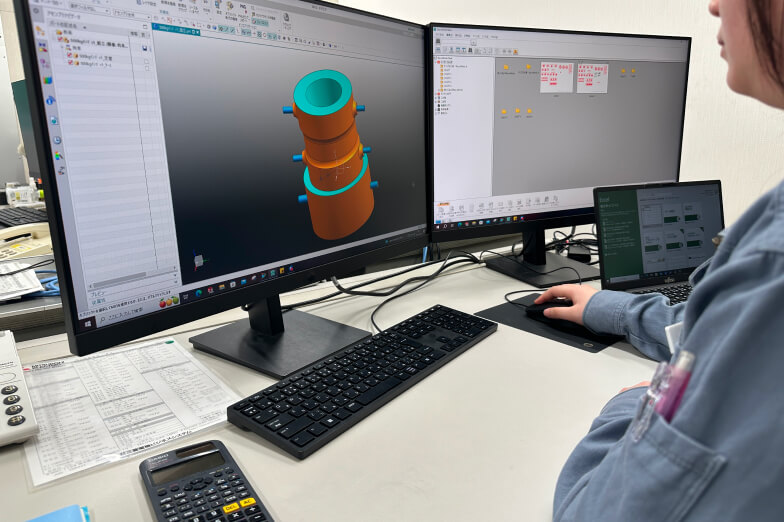

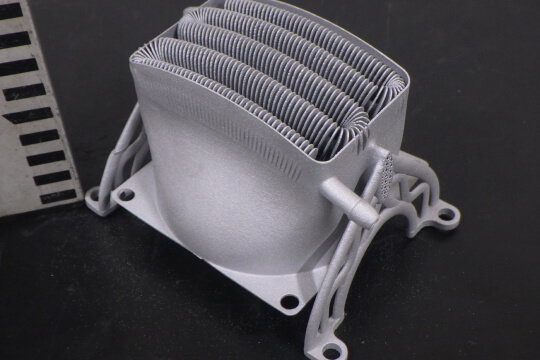

In addition to our traditional expertise in casting and forging, we are pioneering a third pillar of innovation with our cutting-edge metal 3D printing (additive manufacturing) technology.

As demand for 3D-printed products continues to grow, we are advancing the development of 3D products using low thermal expansion alloys (Invar alloys).

Alongside products created with the PBF method (Powder Bed Fusion), we have also adopted the L-WAM method (Laser Welding Additive Manufacturing), which enables the production of larger components at faster speeds.

This expansion of our 3D manufacturing capabilities allows us to meet diverse customer needs while delivering optimized solutions that balance cost efficiency and exceptional quality.