Research Equipment

※ Please click the underlined equipment names for more details.

| Vacuum Induction Melting Furnace (30kg) | For alloy development that is not possible with atmospheric melting | 1 unit |

|---|---|---|

| Vacuum Arc Melting Furnace | For small sample production (φ40×20mm) for alloy development | 1 unit |

| Thermal Expansion Measurement Device | Push-rod type high-resolution device | 5units |

| Vibrating Sample Magnetometer (VSM) | High-precision magnetic measurement | 1 unit |

| Metal 3D Printer(P-DED) | Research and development DED method, build size: 355×355×500mm Max.wt=35Kg | 1 set |

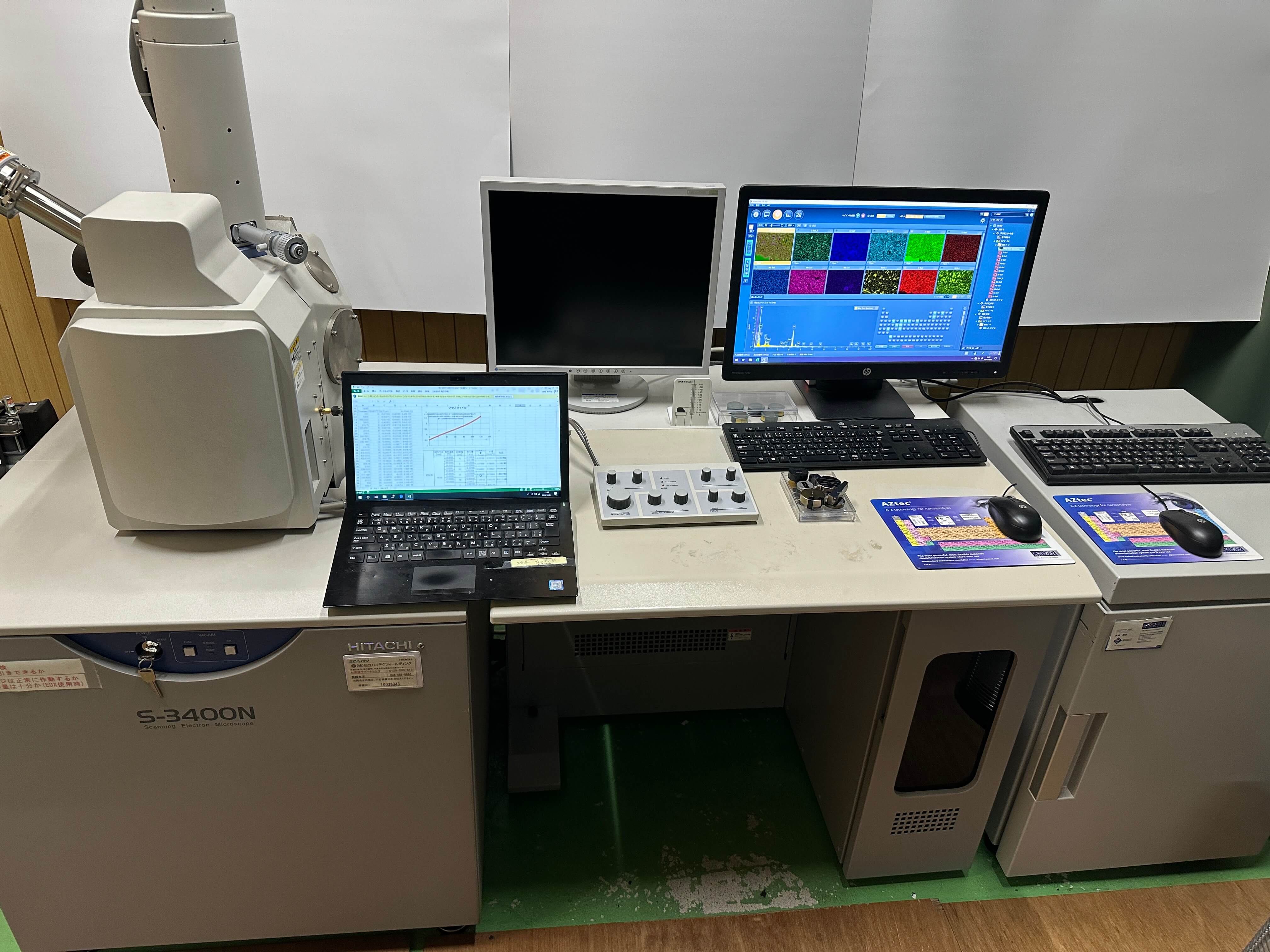

| Scanning Electron Microscope (SEM) | High-magnification observation with EDX analysis capability | 1 unit |

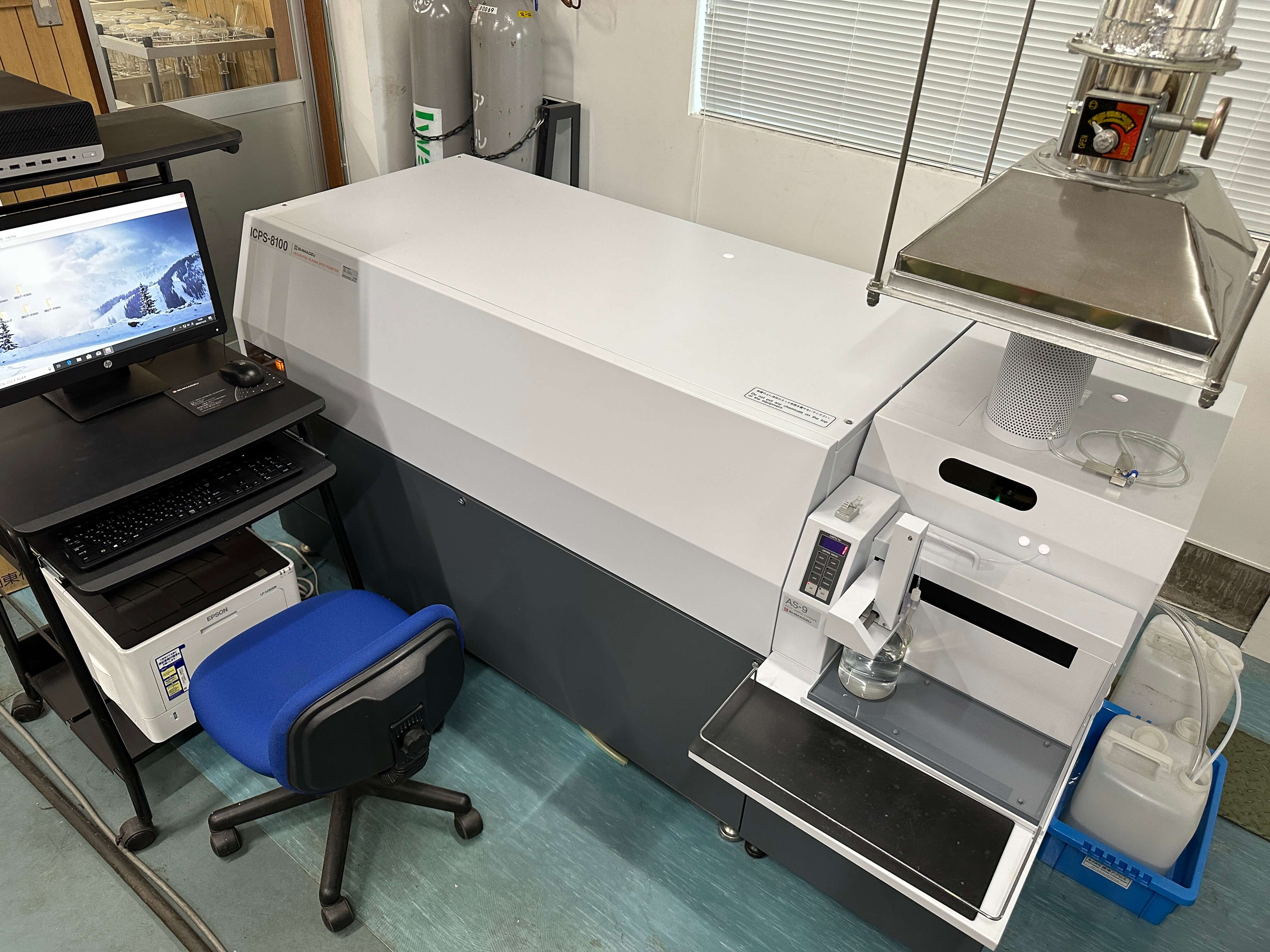

| ICP Emission Spectrometer | Qualitative and quantitative analysis | 1 unit |

| X-ray Fluorescence Analyzer | Qualitative and quantitative analysis | 2 units |

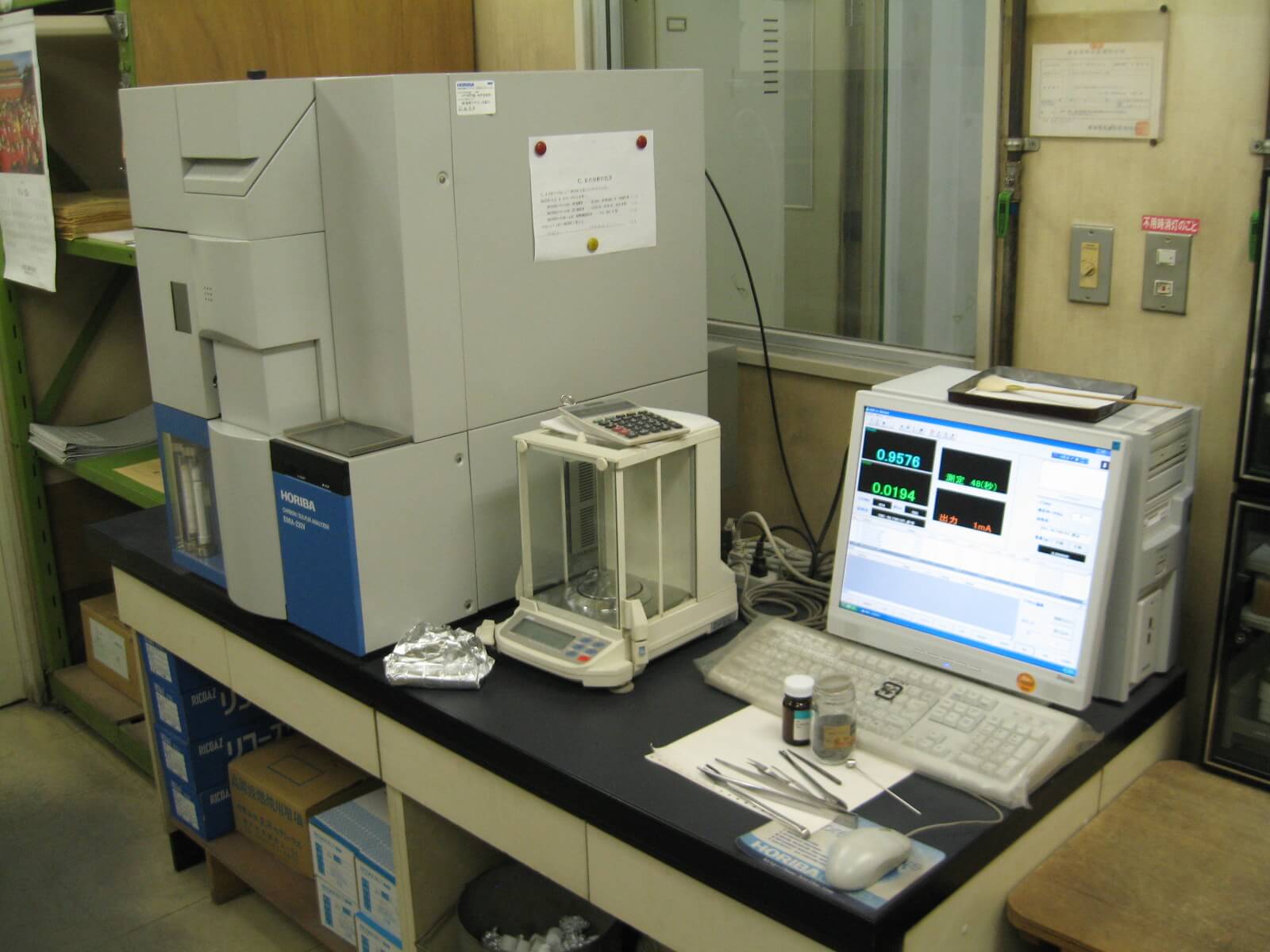

| Carbon-Sulfur Analyzer | Quantitative analysis by infrared absorption method | 2 units |

| Chemical Analysis Equipment | Quantitative analysis by titration | 1 set |

| 3D Laser Microscope | Observation magnification: 100–3000x, Z resolution: 1nm | 1 unit |

| Optical Microscope | Observation magnification: 50–500x (with monitor output) | 1 unit |

| FFT Analyzer | Measures loss factor and Young's modulus (resonance method) using electromagnetic excitation | 1 unit |

| 1000 kN Universal Testing Machine | Tensile testing from room temperature to 1250°C, and more | 1 unit |

Manufacturing Equipment

※ Please click the underlined equipment names for more details.

| Metal 3D Printer (L-WAM) | Mass-production(L-WAM), build size: 1400×1000×1200mm Max.wt=500Kg | 1 unit |

|---|---|---|

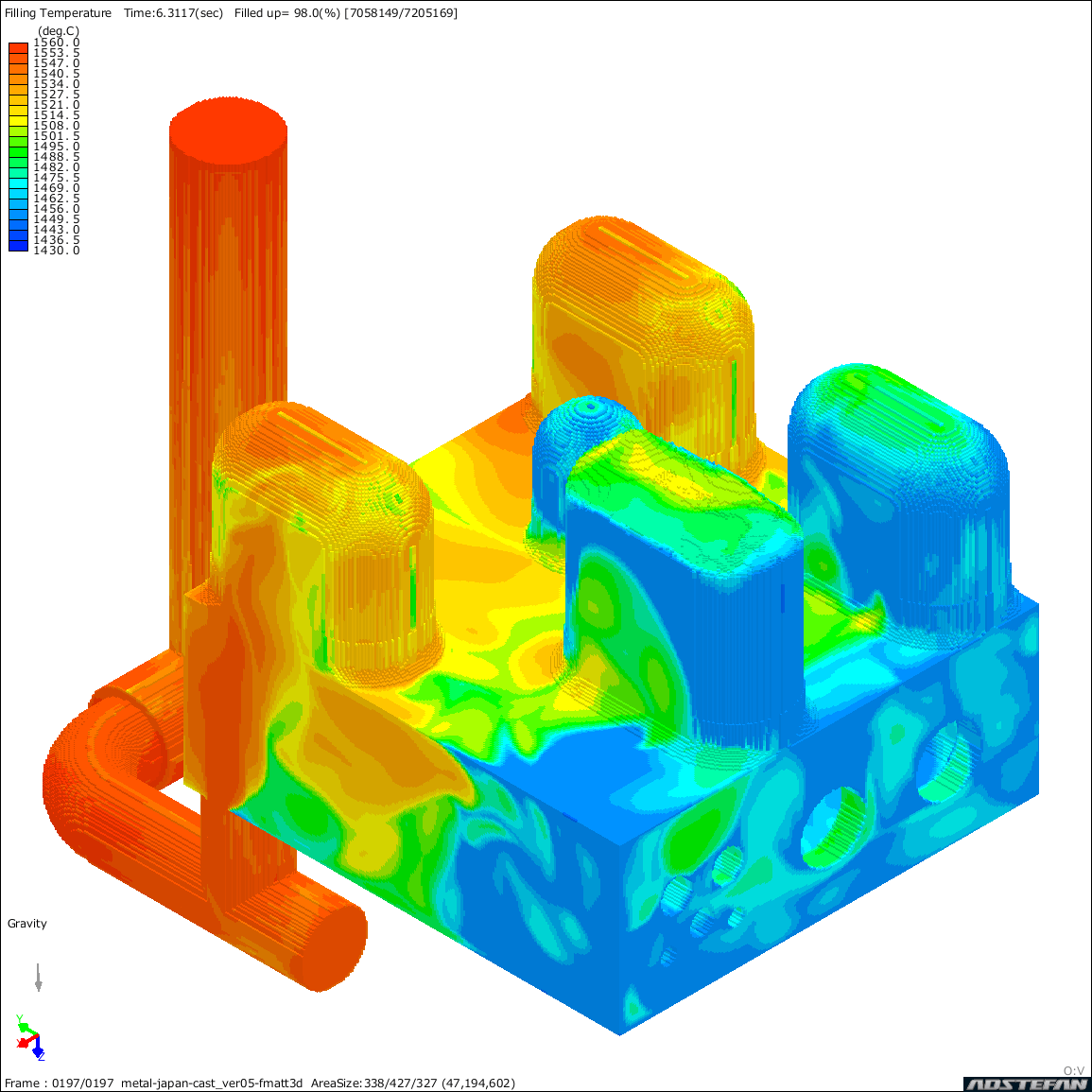

| Casting Simulation Equipment | High-precision simulation with proprietary know-how | 1 set |

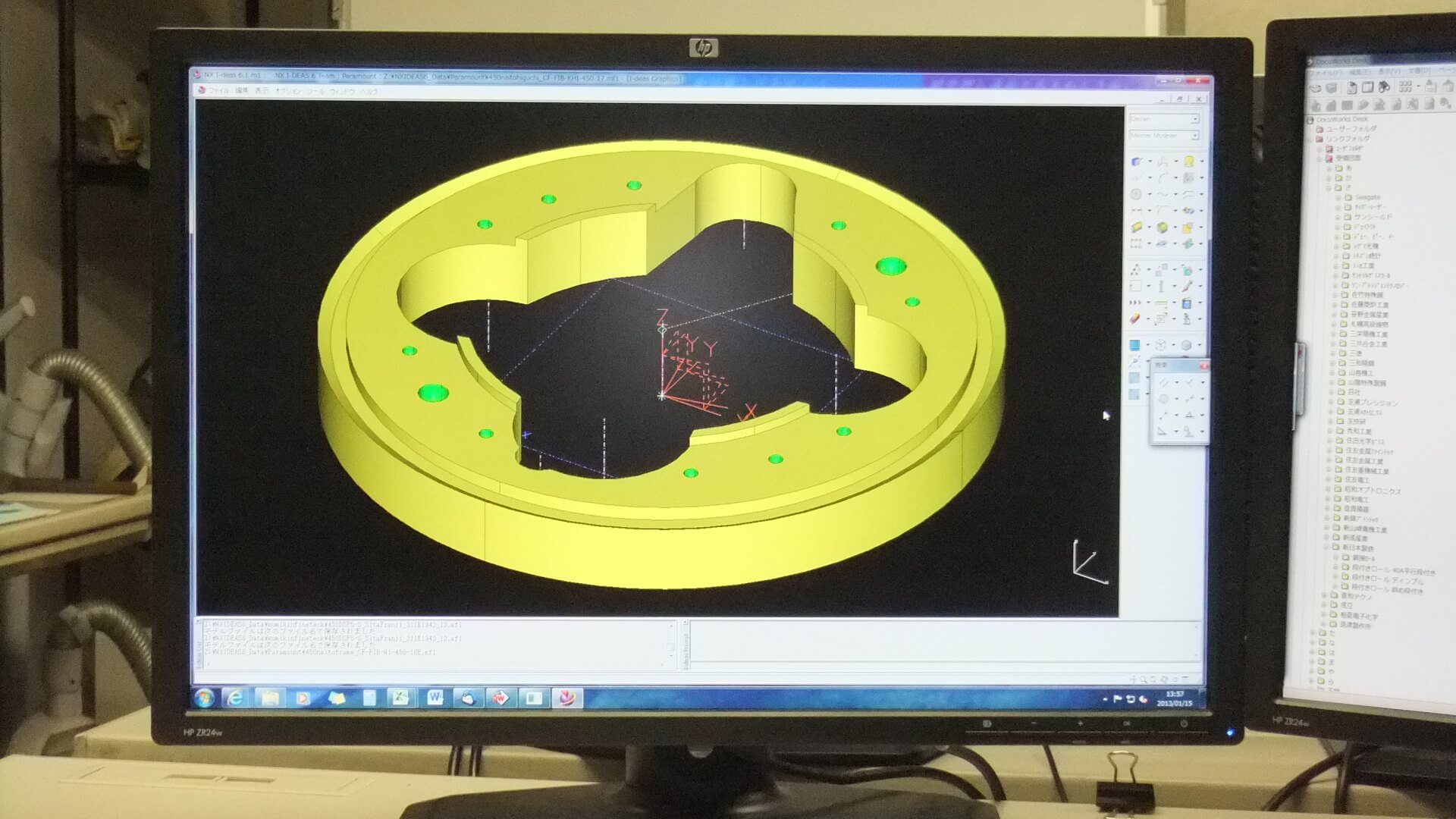

| 3D CAD Equipment | Software: "NX," "NX I-deas," "SolidWorks" | 2 units |

| High-Frequency Melting Furnaces | 3-ton, 2-ton, 1-ton × 3 furnaces, 700kg | 6 furnaces |

| High-Frequency Melting Furnace (100kg) | For mass production testing | 1 unit |

| Acid Demand Value Tester | Muffle furnace FP103 by Yamato Scientific | 1 unit |

| Self-Hardening Molding Equipment | Line type, 20 t/10 t switchable, 5 t | 4 lines |

| Shot Blast Machine | 5t=Φ2500×H3000 | 1 unit |

| Hydraulic 5000kN Press Machine | Mobile type × 1 unit, fixed type × 1 unit | 2 units |

| YAG Laser Welding Machine | Precision welding machine applicable to precision machining surfaces | 1 unit |

| TIG Welding Machines | 300 A × 8 units, 200 A × 1 unit, 250 A × 1 unit | 10 units |

| Precision TIG Welding Machine | SW-VO1 | 1 unit |

| CO2/MAG Welding Machines | 500 A × 3 units | 3 units |

| Low-Temperature Heat Treatment Electric Furnace | 3250×3500×H1600 | 1 unit |

| High-Temperature Heat Treatment Gas Furnace | 7-ton cart type, 3-ton batch type | 2 units |

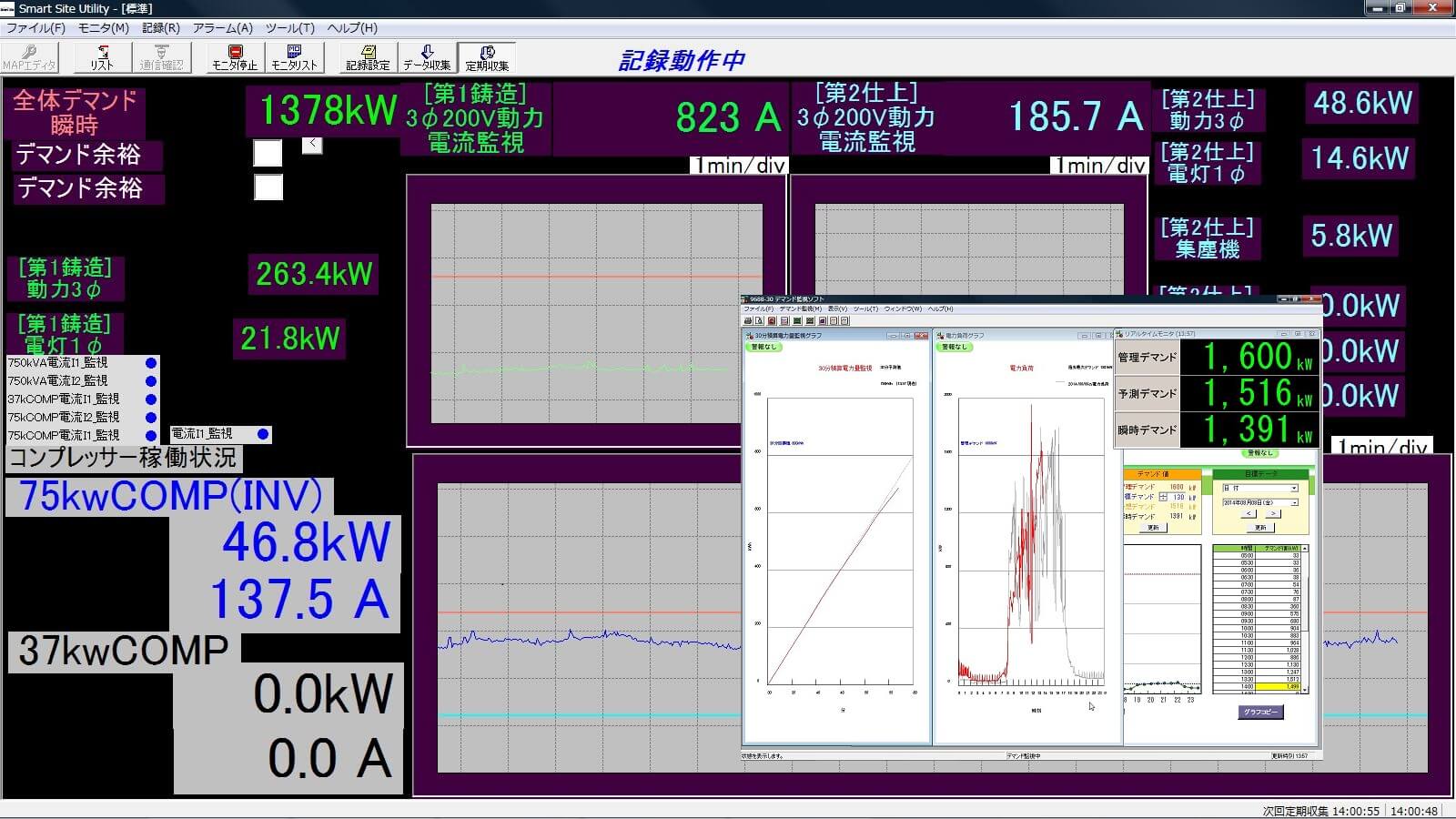

| Demand Management Equipment | Comprehensive management equipment for high-voltage power | 1 unit |

Inspection Equipment

※ Please click the underlined equipment names for more details.

| CNC Gantry-Type Coordinate Measuring Machine | X1200 x Y2000 x Z1500, Measurement Accuracy: 3.5 + 5L/1000 μm | 1 set |

|---|---|---|

| Wide-Area 3D Measurement System | KEYENCE WM Series / Non-contact scanning specifications | 2 units |

| Digital Ultrasonic Flaw Detector | Model: UI-27 | 2 units |

| Horizontal Arm Coordinate Measuring Machine | X1480 x Y2150 x Z1500, Guaranteed Accuracy: 40 μm, Minimum Display: 10 μm | 1 set |

| Layout Machine | X1480 x Y3600 x Z1500, Guaranteed Accuracy: 80 μm, Minimum Display: 10 μm | 1 unit |

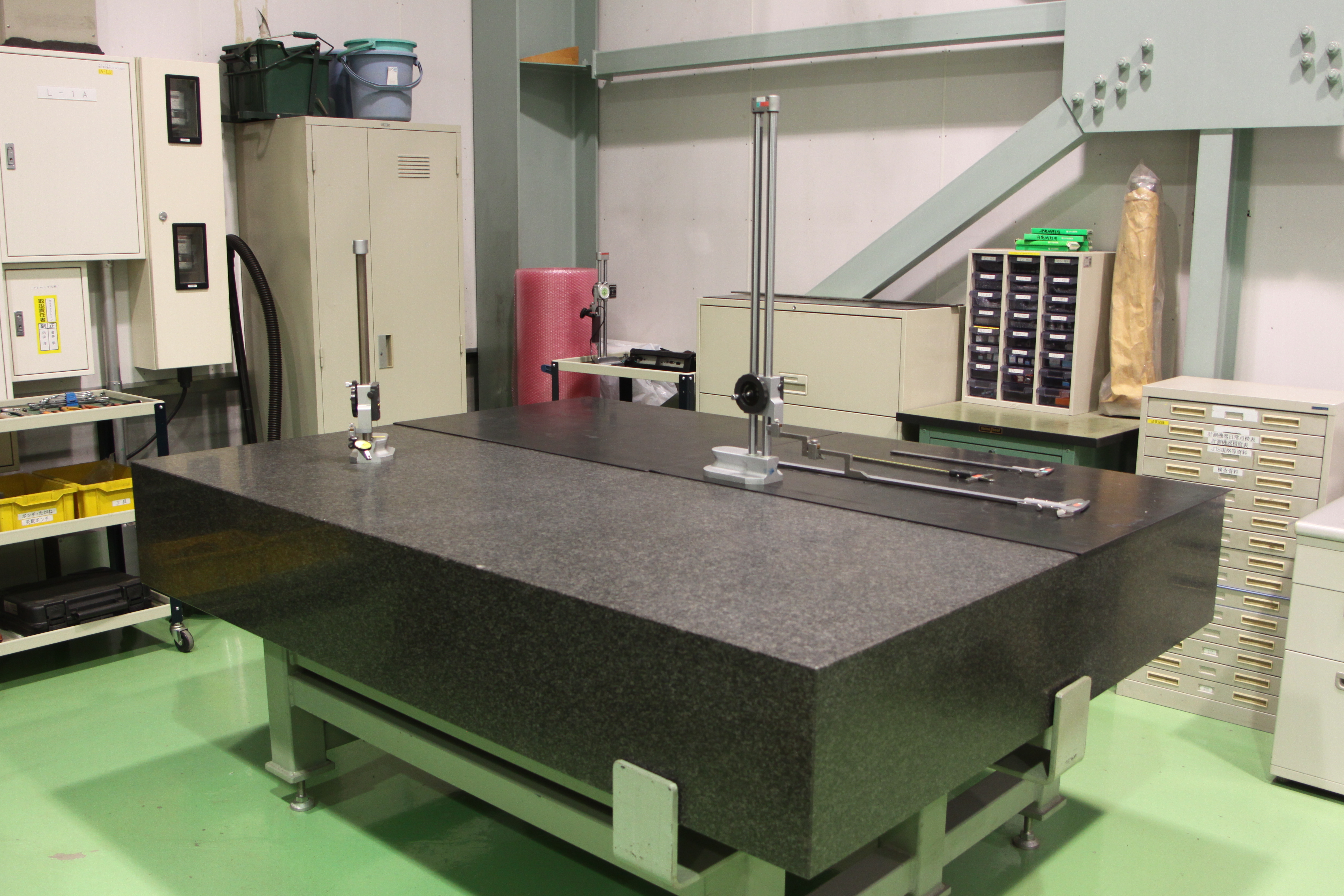

| Precision Surface Plate (Grade 00) | Size: 1500 x 2000 mm, Grade: Grade 00 (5 μm) | 1 unit |

| Large Inspection Surface Plate | 3000 x 3000, 1500 x 2000, 1250 x 2450, 1500 x 3000 | 4 lines |