The pinnacle of alloy design and manufacturing expertise—this is what defines our proprietary alloy materials and product offerings.

Our products are the result of decades of accumulated metallurgical knowledge combined with cutting-edge alloy development technologies. Constantly evolving to meet the diverse demands of next-generation optical devices and advanced industries, our alloys are at the forefront of innovation.

In particular, our consumable products have achieved remarkable advancements in durability by enhancing resistance to chlorine corrosion, oxidation, and wear. These high-value-added alloy solutions significantly extend product lifespans, delivering unparalleled performance and reliability.

With our advanced alloy product lineup, we empower your projects to reach new heights of excellence.

Low CTE alloy (Invar alloy)

While most metals expand when heated, we deliver metals that defy this norm.

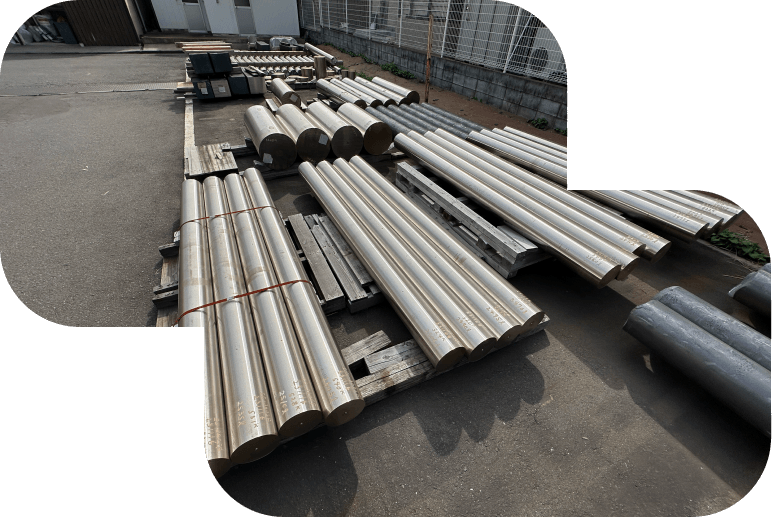

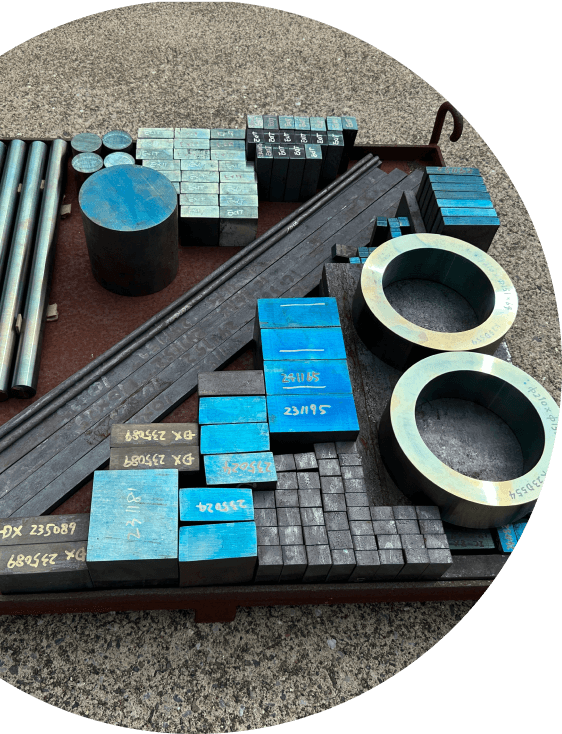

Our low CTE alloys (Invar alloys) have been developed to meet the diverse needs of our customers. With a wide range of options tailored for various applications, our alloys are designed to perform where precision matters most.

At our company, we offer Invar alloys not only as cast products but also in virtually any shape or form. From square and round forged materials to thick and thin rolled plates, we provide solutions to suit your specific requirements.

Note: Rolled products are available in widths up to 250mm.

Discover the reliability and precision of our low CTE alloys for your next project!

| IC-ZX | Ultimate Zero Expansion Alloy Surpassing Super Invar Thermal Expansion Coefficient: 0 ppm/°C Low-Temperature Usage Limit: -20°C Applications: Semiconductor manufacturing equipment, FPD manufacturing equipment, precision measurement and inspection jigs |

|---|---|

| IC-DX | Zero Expansion Alloy with Superior Stability, Rigidity, and

Corrosion Resistance Thermal Expansion Coefficient: 0 ppm/°C Low-Temperature Usage Limit: -269°C Young's Modulus: 176 Gpa Corrosion Resistance: Equivalent to SUS304 Applications: Next-generation large-scale telescope observation equipment, radio telescopes, gravitational wave observation equipment |

| IC-LTX | Zero Invar for Use at -100°C Thermal Expansion Coefficient: 0 ppm/°C Low-Temperature Usage Limit: -100°C Applications: Astronomical observation satellites, infrared telescopes, aerospace-related applications |

| IC-36FS | Free-Cutting Super Invar Thermal Expansion Coefficient: 1 ppm/°C (1/10 of that of iron) Features: Ample material stock available, suitable for small-lot production and quick delivery Applications: Semiconductor manufacturing equipment, FPD manufacturing equipment, optical lens components |

| IC-36 | Standard Invar Thermal Expansion Coefficient: 1.5 ppm/°C Low-Temperature Usage Limit: -200°C Applications: Precision press machines, optical communication devices |

| IC-362A | Corrosion-Resistant Invar Equivalent to SUS410 Thermal Expansion Coefficient: 2 ppm/°C Features: High resistance to rust in neutral environments Applications: Aspherical lens polishing machines, semiconductor manufacturing equipment |

| IC-364 | Customizable Thermal Expansion Invar Thermal Expansion Coefficient: 4 ppm/°C Applications: Components designed for bonding with glass |

| SLE-2 | Corrosion-Resistant Invar Equivalent to SUS304 Thermal Expansion Coefficient: 5 ppm/°C Applications: Components designed for bonding with ceramics |

| SLE-20A | Corrosion-Resistant Invar Equivalent to SUS410 Thermal Expansion Coefficient: 3 ppm/°C Applications: Wafer polishing plates, precision medical devices |

| VIC-65 | High-Temperature Stable Invar Thermal Expansion Coefficient: Stabilized at 5 ppm/°C from room temperature to 350°C Applications: CFRP molds for aircraft, hard glass sealing materials |

| Grade | Physical properties | Mechanical properties | |||||||

|---|---|---|---|---|---|---|---|---|---|

| CTE | Young&s modulus |

Thermal conductivity |

Specific heat |

0.2% Yield strength |

Tensile strength |

Elongation | Hardness | ||

| ppm/℃ | GPa | W/m℃ | J/kg℃ | MPa | MPa | % | HRB | ||

| Zero Invar | IC-ZX | 0 (25~50℃) |

137 | 15 | 500 | 326 | 450 | 36 | 75 |

| Ultra-Low Temperature High Rigidity Zero Invar | IC-DX★ | 0 (-175~25℃) |

176 | 15 | 490 | 212 | 575 | 57 | 76 |

| Low-Temperature Zero Invar | IC-LTX★ | 0 (18~28℃) |

133 | 14 | 485 | 277 | 449 | 38 | 71 |

| Super Invar | IC-36FS | 0.7 (25~100℃) |

136 | 14 | 450 | 308 | 463 | 38 | 71 |

| Invar | IC-36 | 1.5 (25~100℃) |

140 | 15 | 500 | 230 | 400 | 40 | 79 |

| IC-362A | 2.0 (25~100℃) |

141 | 15 | 470 | 364 | 477 | 36 | 75 | |

| IC-364 | 4.0 (25~100℃) |

151 | 14 | 480 | 224 | 439 | 46 | 60 | |

| Stainless Invar | SLE-2 | 5.0 (25~100℃) |

179 | 14 | 470 | 221 | 507 | 48 | 63 |

| SLE-20A | 3.0 (25~100℃) |

160 | 14 | 490 | 216 | 484 | 43 | 65 | |

| High-Temperature Stability Invar | VIC-65 | 4.7 (25~350℃) |

132 | 20 | 490 | 347 | 518 | 37 | 78 |

★Forged alloy only

(note) The property values are representative values obtained by actual measurements.

| Type | CTE | Young&s modulus |

Thermal conductivity |

Specific heat |

0.2% Yield strength |

Tensile strength |

Elongation | Hardness |

|---|---|---|---|---|---|---|---|---|

| ppm/℃ 25~100℃ |

GPa | W/m℃ | J/kg℃ | MPa | MPa | % | HRB | |

| Ductile Invar | 3.5 | 114 | 16 | 480 | 269 | 453 | 30 | 76 |

| Stainless Steel(SUS410) | 10.0 | 205 | 24 | 460 | 541 | 759 | 28 | 99 |

| Stainless Steel(SUS304) | 17.3 | 173 | 16 | 500 | 296 | 626 | 60 | 91 |

| Spheroidal Graphite Cast Iron(FCD450) | 12.4 | 178 | 37 | 480 | – | 754 | 3 | 90 |

| Carbon Steel(S45C) | 12.2 | 207 | 55 | 490 | 637 | 666 | 17 | 99 |

Ultra Corrosion-Resistant EGNIS / Ultra Wear-Resistant [G]

- ・Proven track record with over 50 locations nationwide and numerous in-house hires

- ・Over 100,000 units delivered

- ・Optimal material recommendations based on furnace observation and defect analysis

- ・Shape proposals utilizing fluid simulation

- ・Capable of handling small-lot production

- ・Welding support available

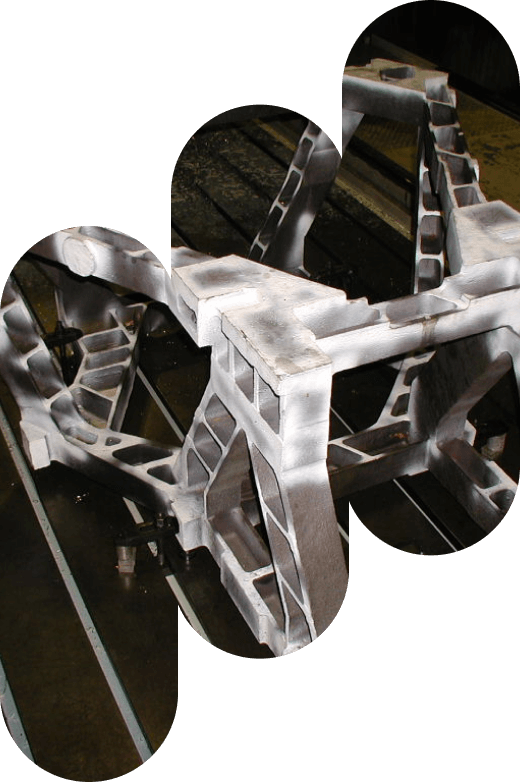

Ultra Corrosion-Resistant EGNIS

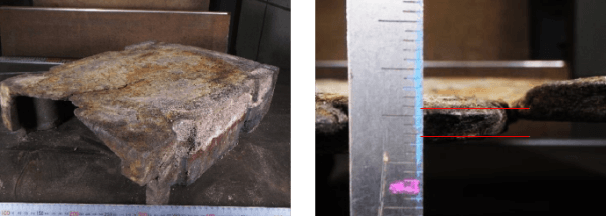

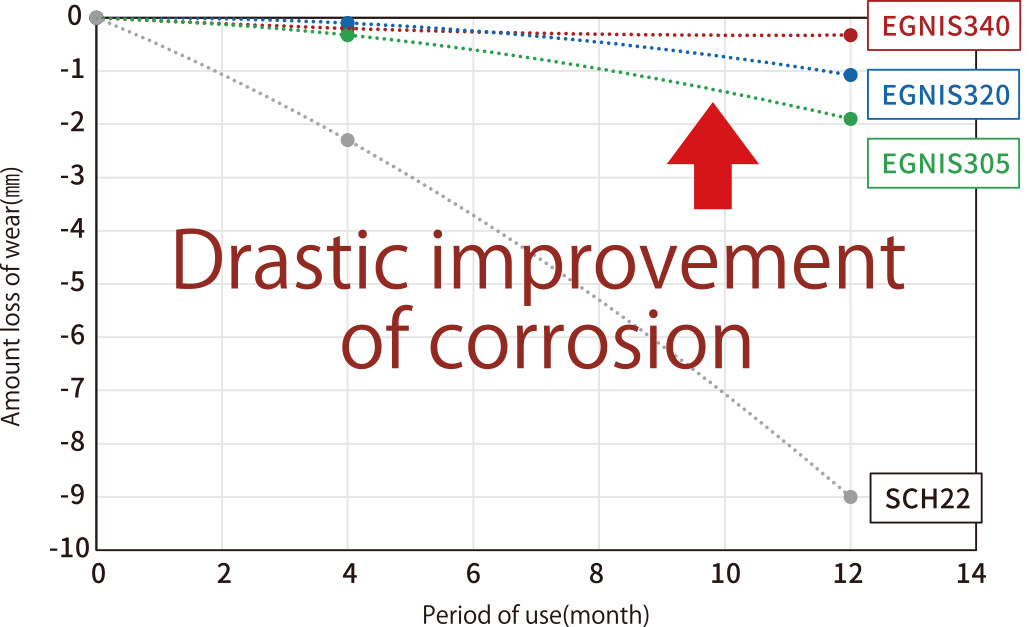

The combustion chambers of incinerators and biomass boilers operate in extreme environments, with temperatures ranging from 500°C to 1000°C and exposure to corrosive chlorine gases. These harsh conditions lead to severe degradation caused by chlorine and oxygen corrosion. Our innovative material, "EGNIS", is specifically engineered to excel in such demanding environments, delivering exceptional corrosion resistance. By utilizing EGNIS, the lifespan of components such as grates and nozzles is dramatically extended, ensuring superior performance and reliability.

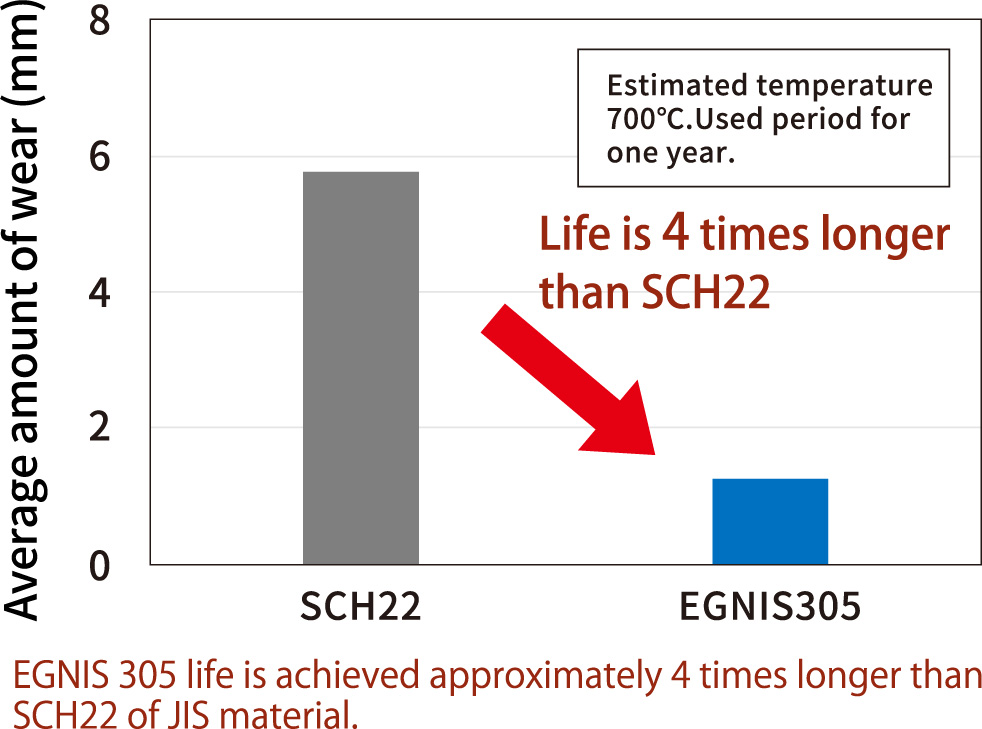

Full-Scale Testing of Stoker-Type Incinerators: 'EGNIS305'

-

EGNIS305

-

SCH22

Oxidation resistance and chloride resistance “EGNIS series”.

-

-

EGNIS340

-

SCH22

-

-

Corrosion Material EGNIS340 EGNIS320 EGNIS305 SCH22 Oxidation ◎ ○ ○ △ Chloride ◎ ○ △ ×

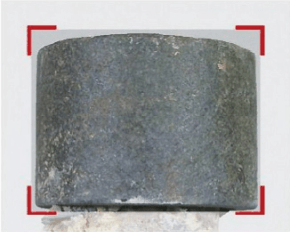

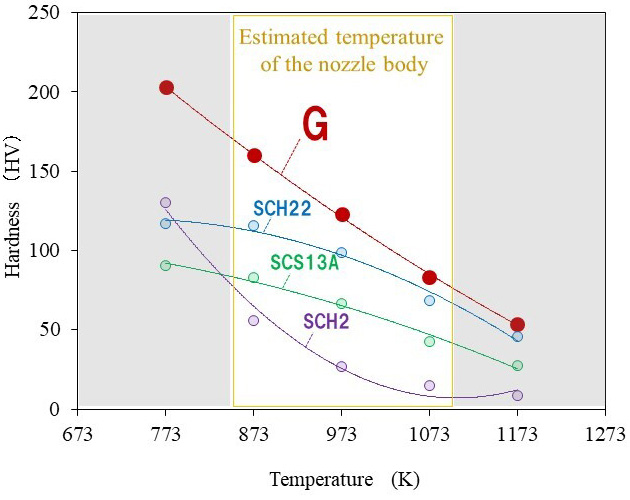

Ultra Wear-Resistant [G]

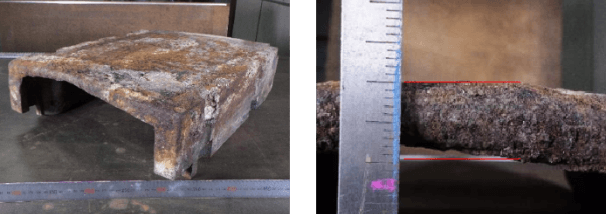

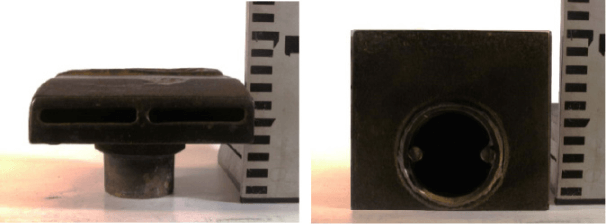

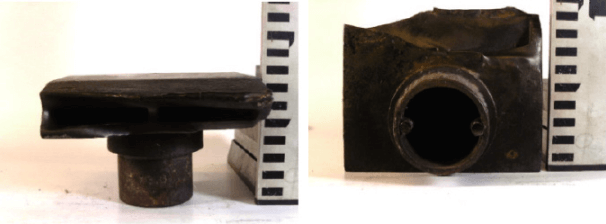

In biomass boilers, air nozzles installed on the furnace floor to stir silica sand are subjected to severe wear due to the impact of the abrasive sand, especially under high-temperature conditions where material hardness typically decreases. Our newly developed "G" material maintains exceptional hardness even at elevated temperatures, offering outstanding wear resistance and dramatically extending the lifespan of the nozzles.

- Features

-

Superior wear resistance at high temperature

Weldable with high toughness

-

「G」 material developed by us.

-

SCH22

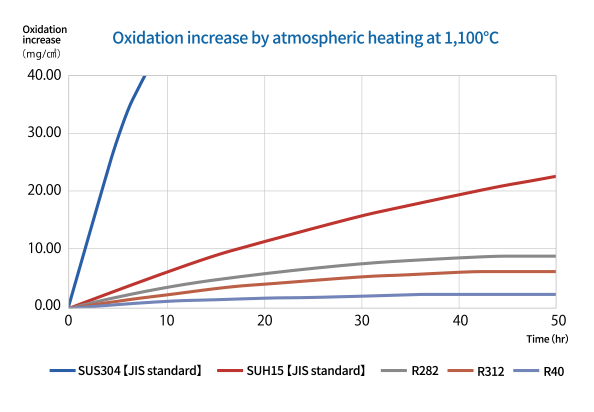

Heat-Resistant Casting Alloys / Wear-Resistant Casting Alloys

Heat-Resistant and Wear-Resistant Metal Materials for Extreme Environments

In the rapidly advancing refractory industry, particularly in steelmaking, the demand for metal materials capable of enduring high-temperature environments is paramount.

Leveraging decades of expertise and innovation in heat-resistant steel production, we have developed cutting-edge super heat-resistant alloys that deliver exceptional performance.

(Key properties: Wear resistance, oxidation resistance, corrosion resistance, creep strength, rigidity, and thermal shock resistance.)

In the manufacturing sector, production lines often involve the transportation of powders, fluids, and other raw materials, which inevitably leads to wear caused by impacts, sliding, and scratching.

Each type of wear requires tailored resistance, and our company excels in meeting these demands. Drawing on extensive knowledge of wear mechanisms accumulated by our R&D and manufacturing technology teams, we provide materials optimized to meet the specific needs of diverse industries.

| PSMT26 | Ni-Based High-Strength Corrosion-Resistant Material (~1100°C) |

|---|---|

| R40 | High-Temperature Wear-Resistant Material (~1100°C) |

| R312 | High-Temperature Wear-Resistant Material (~1200°C) |

| R262 | High-Temperature Oxidation-Resistant Material (~900°C) |

| NWA15 | High-Temperature Oxidation-Resistant Material (~1000°C) |

| NWA13改 | High-Temperature Oxidation-Resistant Material (~1100°C) |

| NAX-TR | High-Temperature High-Strength Material (~1100°C) |

| G | High-Temperature Wear-Resistant Material (~900°C) |

|---|---|

| HP3 | High-Temperature Oxidation-Resistant Material |

| HP10 | Heat-Resistant Material Equivalent to SCH12 |

| HP12 | Heat-Resistant Material Equivalent to SCH13 |

| HP22 | Heat-Resistant Material Equivalent to SCH22 |

| Grade | Composition | Tensile strength (MPa) |

Elongation (%) |

Reduction of Area(%) |

Application |

|---|---|---|---|---|---|

| PSMT-26 | Ni base | 123 | 41 | 50 | Glass fiber manufacturing components |

| R-40 | Fe base | 66 | 10 | 16 | Skid rails for high-temperature zones in heating furnaces (up to 1200°C) |

| R-312 | Fe base | 50 | 69 | 70 | |

| JIS standard product【SUS310S】 | Fe base | 46 | 109 | 68 | Furnace materials, heat treatment tools, and more |

Ultra-Wear-Resistant Cast Alloys

| Material | Composition | Hitting collision | Scratch sera | Slip | Hardness |

|---|---|---|---|---|---|

| I | High Chromium Wear-Resistant Materials | ◯ | ◯ | ◯ | 56 |

| H-2 | Martensitic Wear-Resistant Materials | △ | ◎ | ◎ | 68 |

| P-2M | High Toughness Wear-Resistant Materials | ◯ | △ | ◯ | 54 |

| KM-6 | High Chromium-Tungsten Wear-Resistant Materials | △ | ◯ | ◎ | 66 |

(Note) The hardness values are actual measured values and are not guaranteed quality values.