At the heart of our company lies the "Research and Development Division," the driving force behind our alloy innovation. Approximately 10% of our employees are dedicated researchers, with over half holding doctoral degrees in engineering. These experts work tirelessly to develop, analyze, and test alloys to meet the diverse needs of our customers.

From our flagship low thermal expansion alloys (Invar alloys) used in semiconductor manufacturing equipment, aerospace, and astronomy, to ultra-corrosion-resistant alloys, we continue to pioneer groundbreaking advancements in metal materials.

Our research achievements are shared globally through presentations at various international conferences, showcasing our commitment to innovation.

As we strive to be a company that embodies "Only Best One," we are accelerating our research and development efforts to deliver unparalleled solutions to the world.

Characteristics of the Research and Development Department

-

A research system that responds promptly to needs

-

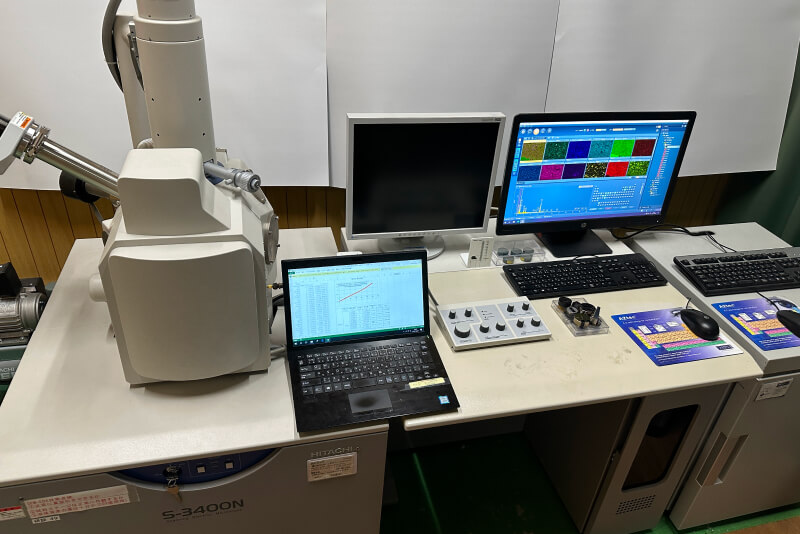

Research facilities supporting development

-

Experimental techniques cultivated over 70 years

-

Material development based on an academic foundation

-

Heritage of precision measurement skills

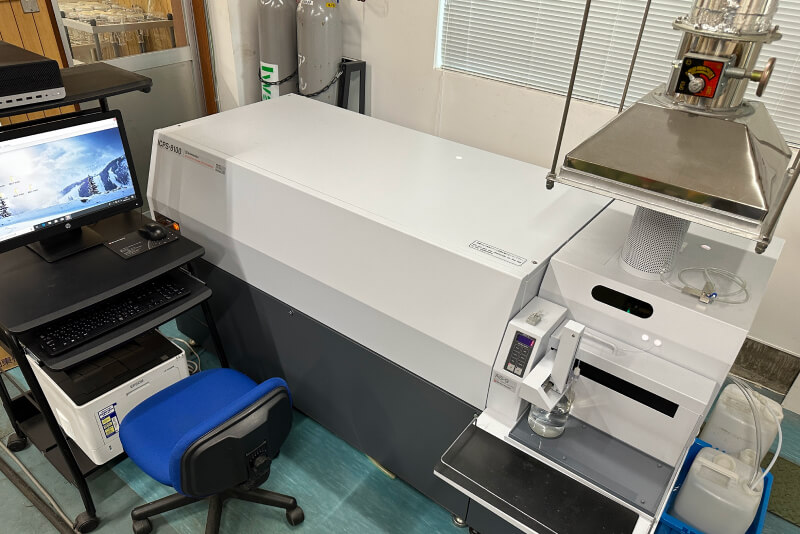

Major research facilities

-

Vibrating Sample Magnetometer (VSM)

-

Scanning electron microscope(SEM)

-

Optical microscope with monitor

-

Thermal expansion measuring instrument

-

30kg vacuum melting furnace for laboratory

-

Inductively coupled plasma optical emission spectroscope (ICP-OES)

R&D accomplishment

CASE1 - Control of CTE (Coefficient Thermal Expansion)

Low CTE alloys (Invar alloys, Anbar alloys) are often used in applications where minimizing thermal expansion due to temperature changes is critical. However, there are cases where simply achieving a low thermal expansion coefficient is not sufficient to meet our customers' specific requirements.

For instance, when the thermal expansion coefficients of Invar alloys and other components in the same assembly differ (bimetallic effect), the desired performance of the equipment may not be achieved. One example involved a request to develop an alloy with the same thermal expansion coefficient as a specialized ceramic material.

By adding specific elements to the primary chemical composition of the base Invar alloy, we were able to precisely control the thermal expansion coefficient, matching it to that of the specialized ceramic. This enabled the equipment to achieve its intended performance.

At our company, we can provide low CTE alloys (Invar alloys, Anbar alloys) with CTE tailored to match other materials, down to 1 ppm precision. Furthermore, in recent years, we have been actively developing Invar alloys with near-zero CTE, capable of performing under a wide range of temperatures and environmental conditions.

CASE2 - Prolonged life of heat and wear resistant tool at harsh environment

Tackling Extreme Environments with Advanced Alloys and Tools

Seamless pipe piercing tools, upstream processes in steel mills, glass wool manufacturing, and biomass power plant boilers all operate under extreme conditions, facing challenges such as wear, seizing, cracking, deformation, and corrosion.

To address these demanding applications, we meticulously analyze operating conditions and failure causes, optimizing combinations of alloy design, heat treatment, and surface treatment. This approach has successfully extended the lifespan of hot-working tools and components.

One notable example is the development of our ultra-corrosion-resistant alloy, "EGNIS." High-temperature corrosion caused by chlorine or molten salts is beyond the tolerance of most commercially available materials.

To combat such severe corrosion, we created the "EGNIS" series. This alloy was developed through extensive real-world testing, verification, and analysis in collaboration with numerous companies. It is a testament to our unique approach of working hand-in-hand with users to co-create solutions tailored to their needs.

Our commitment to innovation and partnership ensures that our alloys and tools are ready to meet the toughest challenges in the most demanding environments.